- Bus stop available

Steinbergruine

Historical site | Viewpoint/observation tower

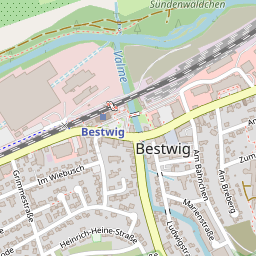

Address

Steinbergruine

Auf dem Steinberg

59909 Bestwig

Telephone: 02904-712810

Properties:

This chimney marks an important technical, economic and local historical time window in the history of the municipality of Bestwig and the Ramsbeck mining district between 1854 and 1860. The ores found in the 140 km² Ramsbeck mining district - first mentioned in a document in 1518 - were smelted into lead, zinc and silver. The importance of this mining district at the time for the Archbishopric of Cologne, the lord of the manor, led to Ramsbeck being granted mining rights in 1559.

In the following decades, the Ramsbeck mining district experienced economic ups and downs, but in 1815, the merger of mining companies to form the Ramsbeck trade union led to calmer waters. An economic boom phase, a veritable development frenzy, set in with the takeover of the Ramsbeck mines by the Stolberg company in 1854, whose general director Henry Marquis de Sassenay pursued the goal of developing the largest industrial center in Europe in Ramsbeck. He aimed to produce 15,000 tons of lead and 22,000 tons of zinc per year, and

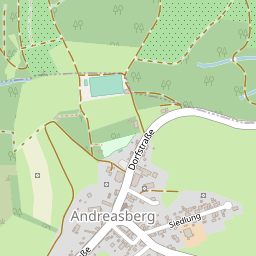

in order to expand the existing mining operations accordingly, around 1,000 miners were recruited from the Harz Mountains, among other places, and settled in new establishments such as Neu-Andreasberg. In addition, punching plants for processing the ore and other facilities were built, as well as two

smelters

for the planned processing of 30,000 tons of lead ore

, one of which was built in Ramsbeck and the other in Ostwig, the Friedrich-Wilhelm-Hütte. Around 1 million thalers were invested in the latter site alone, and

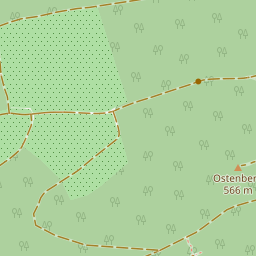

both smelters were located in valleys. As a result, the highly toxic waste gases and dust produced during the smelting process had to be discharged into higher layers of air above the mountain ridges in order to reduce environmental pollution in the floodplain areas. This task was solved by constructing two-pass waste gas ducts, the so-called foxes, from each of the two huts up the slope, which led into chimneys at a certain height above the valley. The natural draught in the system then allowed the exhaust gases to be discharged into the upper layers of air, and

the technicians of the time had few resources at their disposal for a cost-effective solution to these tasks, above all the locally available quarry stone and lime mortar. This explains why the foxes, which were deepened into the ground and constructed with square cross-sections, were made of quarry stone with quarry stone cover slabs. The foxes are two-track so that a fox can be shut down during operation and the deposited dust can be removed.

only three other plants with this function can be found in the Federal Republic of Germany today. One of them is located in Saxony, a double plant in Rhineland-Palatinate and the third in the neighboring town of Ramsbeck

, but as the yield of the ore deposits in the Ramsbeck mining district had been grossly overestimated, the company collapsed like a house of cards on March 29, 1855 and the general director left behind a mountain of debt of over 3,500,000 thalers. As a result of this collapse, construction of the Friedrich-Wilhelm-Hütte was discontinued with the further construction of the flue gas chimney and the smelter itself was later demolished. Today, the only reminder of this boom period is the flue gas chimney with its fox on the crest of the Steinberg; however, the subsequent economic collapse also plunged many workers and miners in this mining district into social misery and triggered an unimaginable wave of emigration

. 1974 saw the municipality of Bestwig carry out repairs to the chimney on the Steinberg in order to preserve this contemporary witness. In 2009, the municipality carried out a further extensive repair because the weather had caused considerable damage to the quarry stone masonry and the network of joints. These repairs were financed with federal, state and municipal funds, and

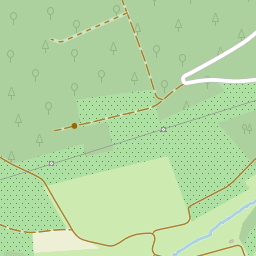

in order to not only preserve this flue gas chimney as a contemporary witness, but also to give it another function, a steel spiral staircase was installed inside to allow visitors a view over the Elpe valley and the village of Ostwig. The Ostwig associations, supported by funds from the NRW Foundation for Nature Conservation, Heritage and Cultural Preservation in Düsseldorf, campaigned for this use and its financing. (Dipl.-Ing. Christian Hoebel)

Prices

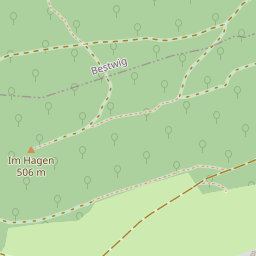

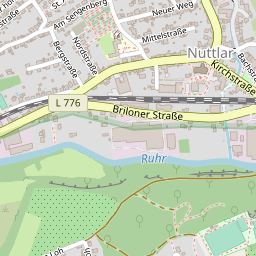

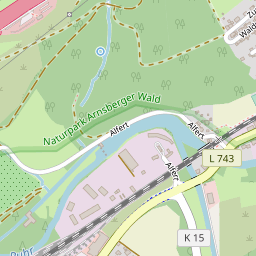

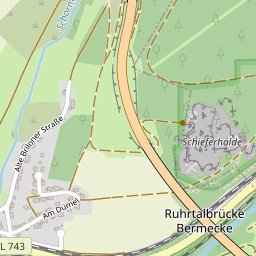

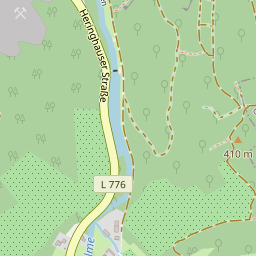

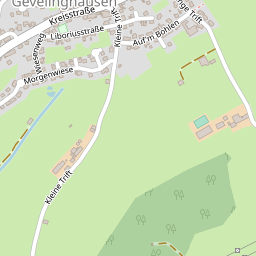

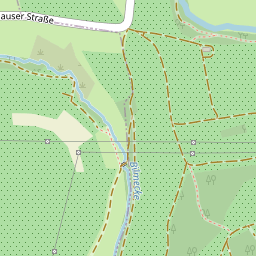

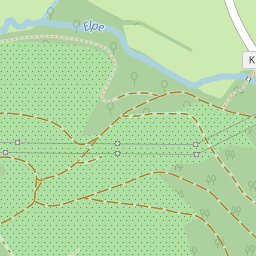

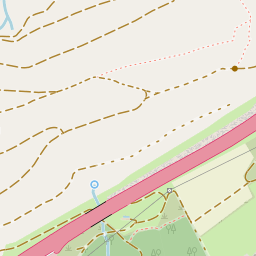

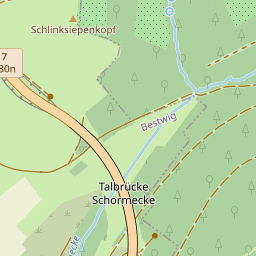

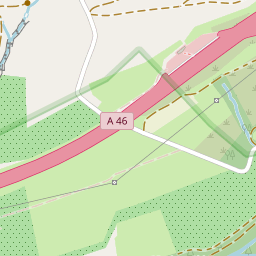

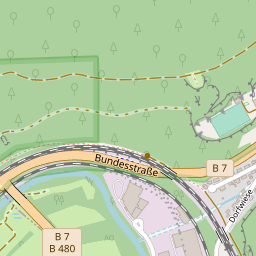

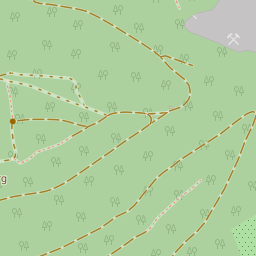

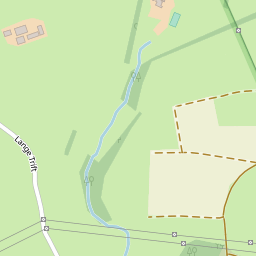

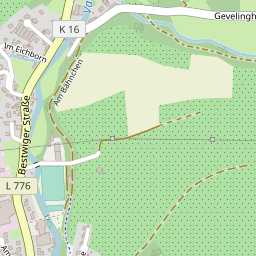

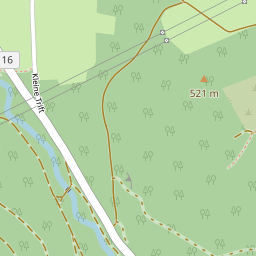

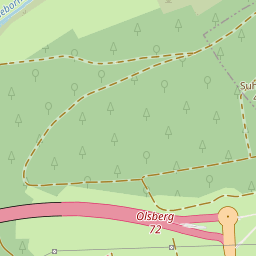

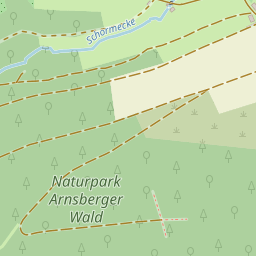

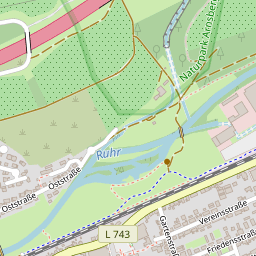

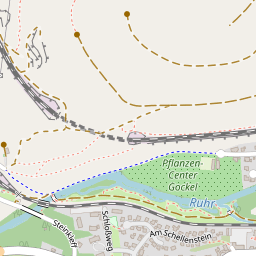

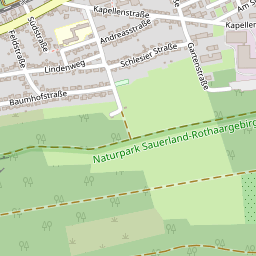

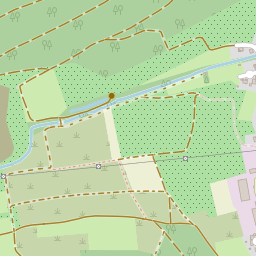

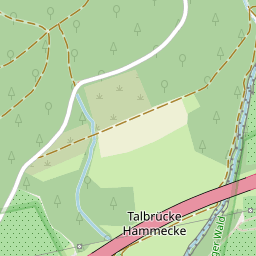

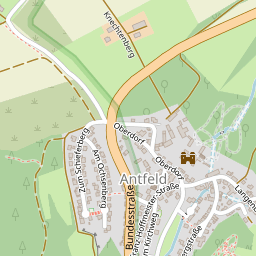

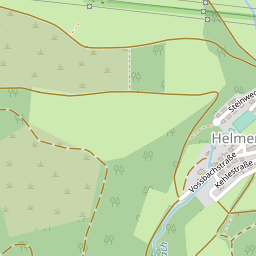

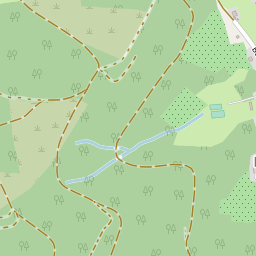

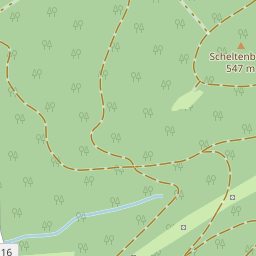

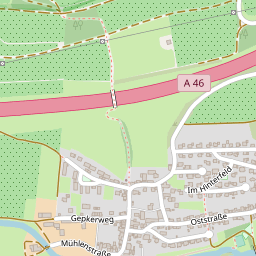

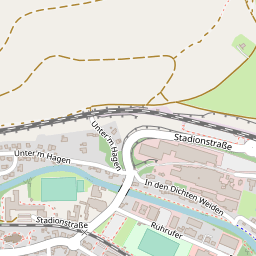

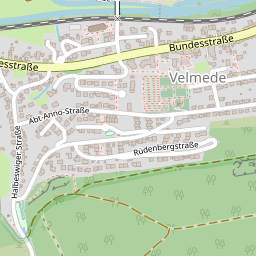

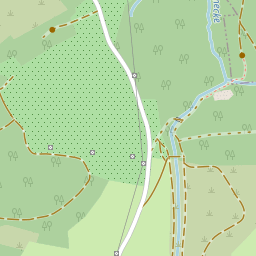

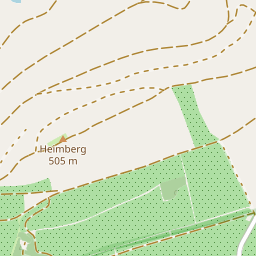

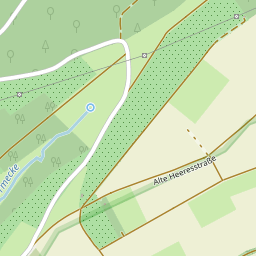

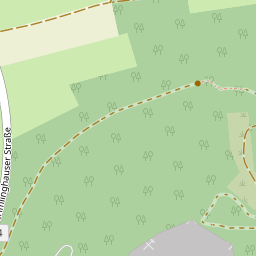

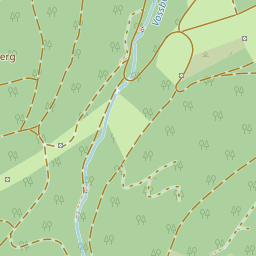

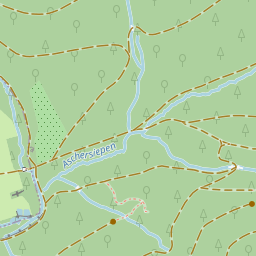

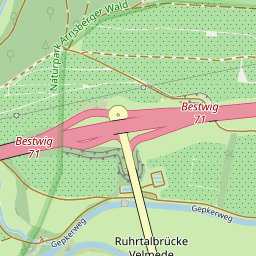

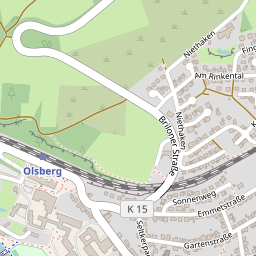

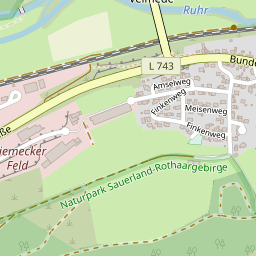

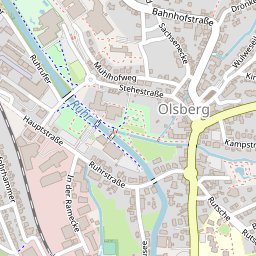

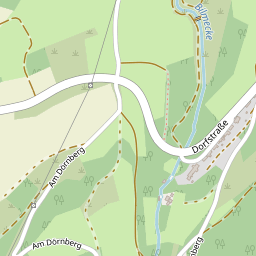

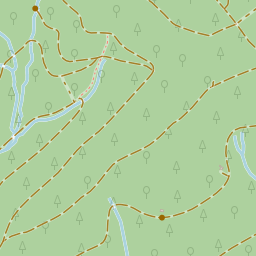

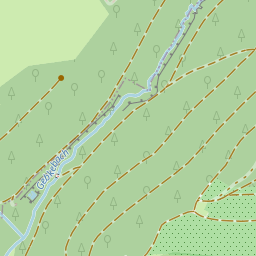

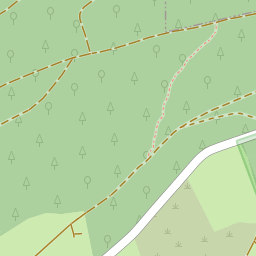

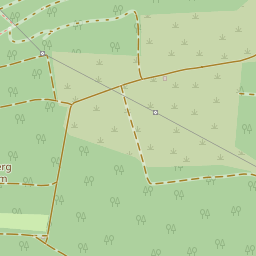

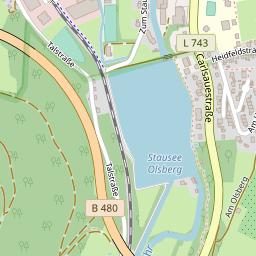

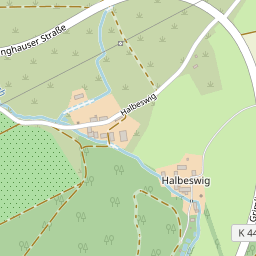

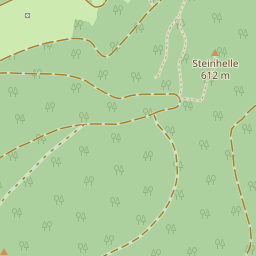

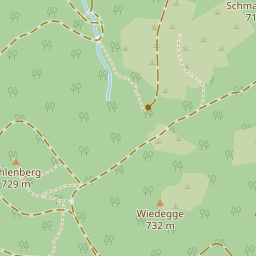

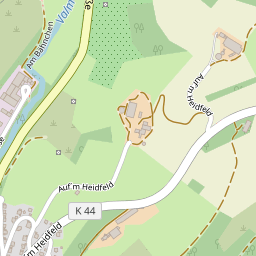

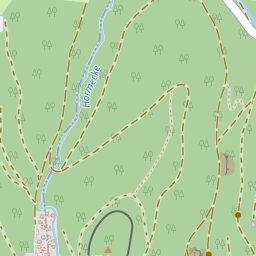

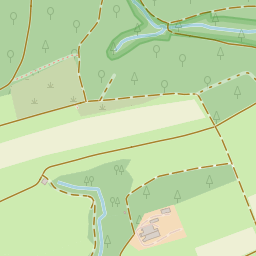

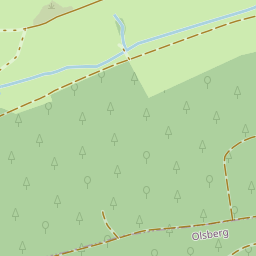

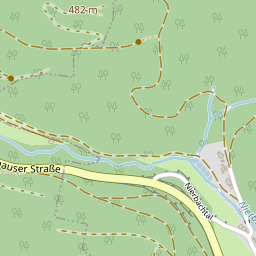

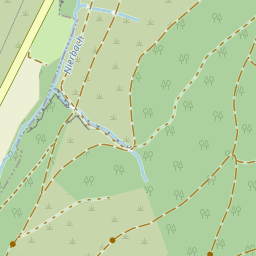

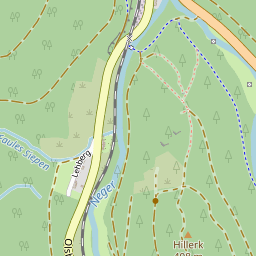

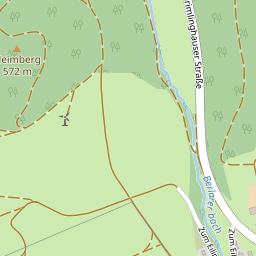

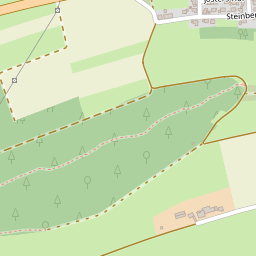

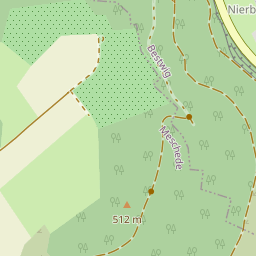

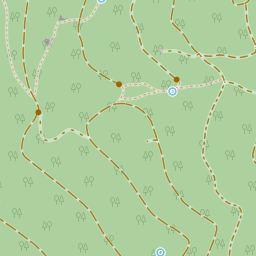

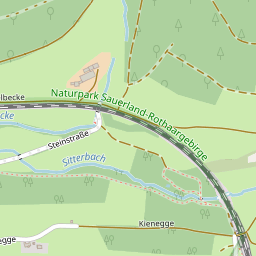

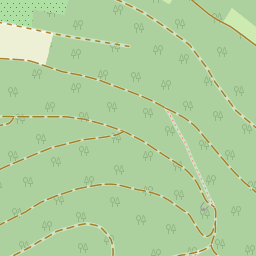

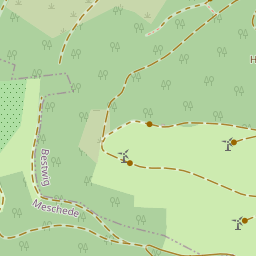

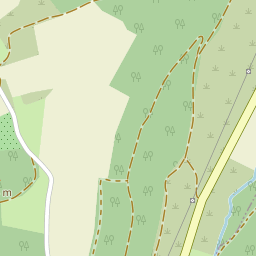

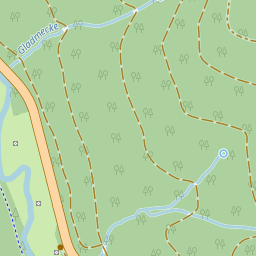

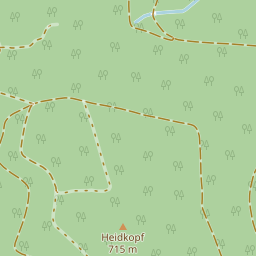

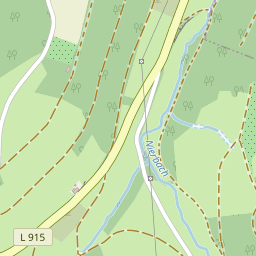

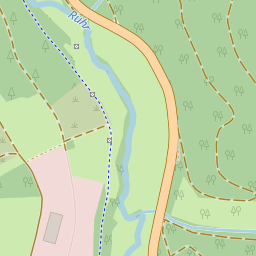

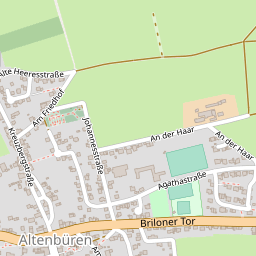

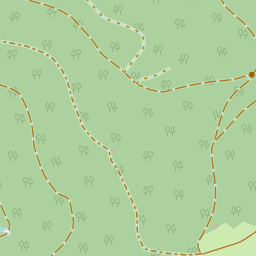

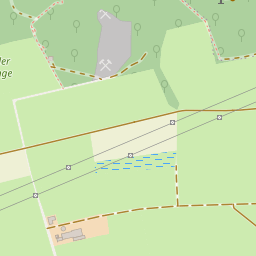

Directions

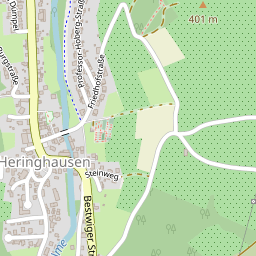

The Steinbergruine can only be reached on foot. The nearest bus stop is Ostwig, Schützenhalle. From here it is approx. 1000 m on foot (steeply uphill) to the Steinbergruine.